EC8 Kit-set plasterboard

A self-proclaimed ‘jack of all trades’, founder Chris Staal has developed technology that supplies pre-cut plasterboard to building sites ready for installation.

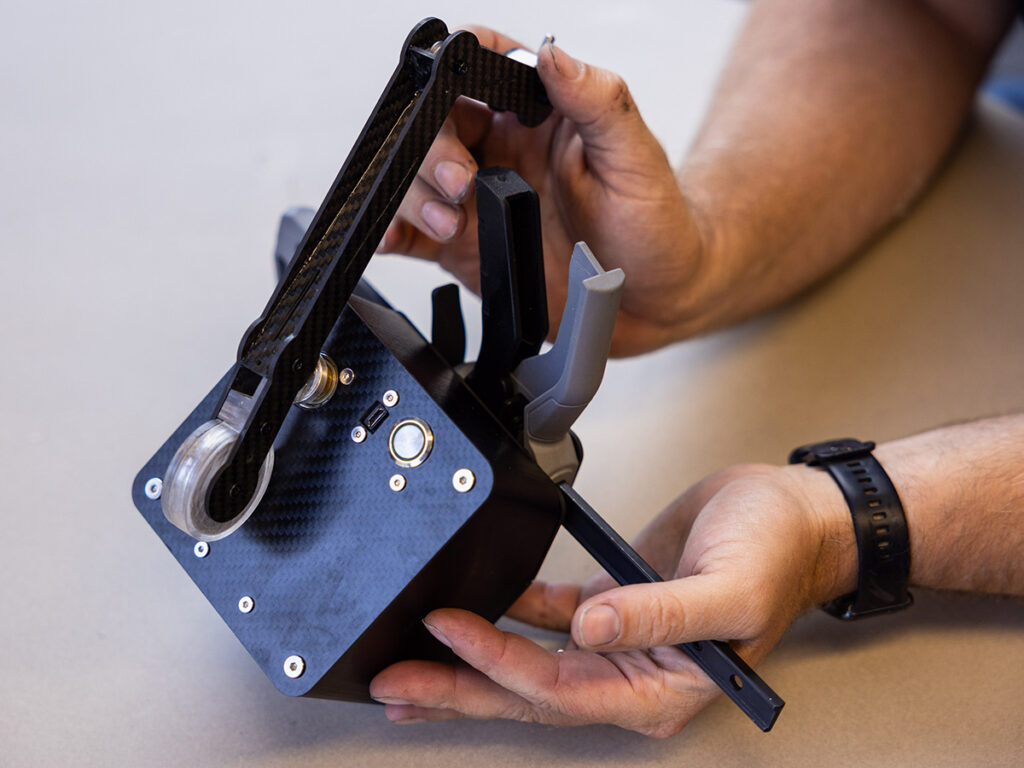

The end-to-end solution allows builders to digitally measure wall dimensions as a 2D model which get uploaded to an easy-to-use app. They then send their order to the EC8 factory, where a custom-built machine robotically picks, cuts and stacks sheets ready to be delivered to building sites.

EC8’s measuring device will take builders around two minutes per wall.

“Hanging plasterboard is a bit like painting: 80% of it is tedious prep work and 20% is the fun part. We do the prep so builders can get straight to hanging,” says Chris.

With trials wrapping up, Chris says the technology reduces build costs, overall build time of a residential house by up to two days and decreases plasterboard waste by up to 30%.

A “genuinely supportive tech community”

The result of four years of ideation, development, testing and trialing, Chris says getting the technology to this point has been no mean feat.

“It’s amazingly complex to get something like this off the ground. We’ve developed three or four pieces of extremely complex software with many prototypes and redevelopments along the way. And same with the hardware. All of that before we’ve made our first dollar.”

EC8’s app records measurements ready for builders to place orders.

Despite these challenges, Chris says his success has been supercharged by Hamilton’s “collaborative and supportive” tech network.

“We’ve received tremendous support from Hamilton business incubator Soda which included a mentorship programme. Through that, we were lucky enough to be guided by the now Spark Health CEO, John Macaskill-Smith, who has been completely invested in the project and instrumental to our success.

Chris with mentor John Macaskill-Smith.

Waikato University has also been a great partner in terms of research and development. We’ve collaborated on two student projects – the first to develop a robotic lifter for drywall and the second around using lidar to digitally measure walls.”

According to Chris, fellow entrepreneurs and tech people in the region are genuinely enthusiastic about lending a hand.

“The tech sector here is buzzing. And everyone I’ve met has been passionate about supporting each other. Even if they can’t personally help, they’re willing to put you in touch with their networks. Ex product development manager, Derek Pinkerton, for example, heard what we were doing and gave up his time for free to guide us which is pretty special.”

Finding tech talent

Alongside the benefits of being part of a connected tech sector, Chris is impressed with the talent he’s found in the Waikato.

“There’s seriously good talent coming out of the University of Waikato. Our mechanical engineer, for example, who was up for Student Engineer of the Year at the Engineering New Zealand Awards in 2023, is the brains behind our robotic loader. Not many people could do what he’s done just two years out of uni.

“And Hamilton is a relatively easy place to attract talent because of the lifestyle it offers.”

Chris with EC8’s mechanical engineer, Taine Whare.

Why Hamilton

When it comes to choosing Hamilton as a base, Chris says “it just made sense.”

“My wife and I had lived here before and loved it. From a business point of view, it’s easy to get intel, there are plenty of suppliers here and everything we need in terms of technical support. It also made sense in terms of a growing market for houses.

“When it comes to family, there are good schools here and it’s an accessible city which means there’s plenty of choice here when it comes to choosing where to live and what lifestyle you want to lead. We’re keen cyclists and spend loads of time riding the river trails.

“Taking everything into account, including lifestyle, access to talent, support and operating costs, I’d choose Hamilton again in a heartbeat.”

Looking ahead

Chris and the team have their sights set on mid-2024 to go commercial, with improvements to the software and hardware ongoing.

The long-term plan is to lease the technology on a subscription model and provide customers with their own cutting machines.

“Five years from now the aim is to be exporting good volumes of technology overseas and to have made a real difference to the building sector.”